RETROFITS / On-Site Service

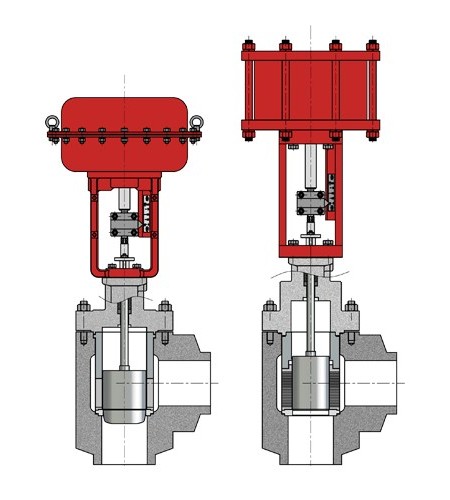

In general, problems with control valves have been rectified by repairing or replacing outdated valves with the plant shut down, resulting in huge time and cost involved. To help improve the situation, BFS offers a solution, quick retrofitting of the control valve by only changing its internal parts while installed, which results in customer satisfaction in performance and time and cost savings.

This retrofit process includes an engineering survey of the entire operating conditions and system and maintenance aftermarket support.

An engineered solution incorporating BFS designed trim into an existing valve body

Fit into most globe and angle cage guided valves

BFS complete responsibility of the retrofitted valve..

Full documentation provided.

Replacement parts available.

Provide advanced technology into existing valve bodies.

Benefit of Retrofit

Improved performance over existing hardware.

Lower installation costs

; No cutting and no welding.

; No pipe modification for different face to face dimensions.

Easy funding from maintenance budgets.

Lower risk than buying a new valve

Minimized Plant down time.

Solution to unavailable parts for older valve..

Retrofit Application

Auxiliary feed-water control valve

Feedwater Main control valve

Feedwater Recirculation control valve

Feedwater Minimum flow control valve

Attemperater spray control valve(HP/LP)

Reactor water cleanup control valve

Condensate recirculation control valve

Auxiliary pump recirculation control valve

Recirculation, DA level control valve

Steam let-down, control valve

Auxiliary Stem control valve

Condenser steam dump control valve

Atmospheric steam dump control valve

Turbine Bypass(HP/IP/LP) valve

Wellhead choke valve

Compressor recycle control valve,

Compressor anti-surge, valve

Water injection control valve

Injection control, valve

Gas to flare

Severe Service Control Valves

Jawa Tengah - Batang